|

Removal:

Begin by breaking loose the lug nuts on

the front right wheel. Then jack up the front of the car and place the jack

stands underneath. Remove the wheel to make more room. Remove the lower

fender liner also. There should be 3 10mm bolts and 3 plastic snaps that

hold this on. |

|

|

|

Next, drain the oil by removing the drain

plug (14mm). Also remove the oil filter. Let the oil completely drain.

Remove the numerous 10mm bolts that hold the lower oil pan on. Once all the

bolts are removed, you will need to pry the pan off because it will be stuck

on with the gasket. A method that works is to stick a pry bar in-between

the block and oil pan. Tap it in with a hammer, then pry it apart. When

the pan is removed, you will be able to see the oil sump and the balancer. |

|

|

|

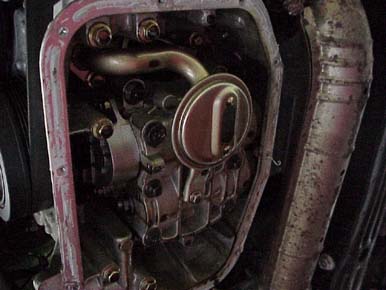

There are two bolts holding the oil sump

on. One is a 10mm bolt that bolts to the balancer. The other is a 12mm

bolt near the top of the oil sump. Remove these bolts and wiggle the oil

sump off. There is an o-ring at the top that keeps it from falling down

after unbolting it. |

|

|

|

Notice the balancer chain guard in the

picture above (on the left). There are two bolts that hold this on. These

must be removed. Use an open end 10mm wrench to loosen these bolts all the

way. One bolt will be easy to get out, however, the other will hit the

front cover. You must loosen it completely, then use a cutting device (such

as a Dremel) to cut the head off the bolt. This will allow room to pull it

out. When both these bolts are removed, you will be able to remove the

balancer chain guard and see the chain. |

|

|

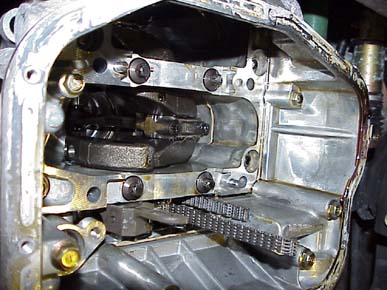

| The next step is to cut the

balancer chain. Again, using a cutting device, cut the chain. |

|

|

|

After the chain is cut, the balancer can

be removed. You will need an E-14 Star socket to remove the main bolts.

There are four bolts that hold the balancer on. Remove the four bolts. The

balancer will not want to come out, but it will if you wrestle with it. It

will take some maneuvering and prying, but it will come out. When it is

removed, it will look like this: |

|

|

| In order to get the chain

out, you must remove the tensioner. It is easiest to remove the yellow part

of the tensioner (by sliding it off), then swing the tensioner up as far as

you can. |

|

|

|

Use a 10mm open end wrench to loosen the

top bolt of the tensioner. This is a tedious job and is hard to get out.

But it is possible. Once the tensioner is removed, you can remove the

balancer chain. |

|

|

|

You will notice there is one oil galley

that was previously feeding oil to the balancer. Use a 1/4" drill bit and

drill into this oil galley about 1". Next, use a 1/16" NPT tap, and tap the

hole. Use compressed air to blow through the hole where the oil filter

goes. Make sure the entire area is free of shavings and dust from drilling

and cutting the chain. Take a 1/16" NPT plug, apply red loctite, and screw

it in to the hole until it fits snugly. |

|

|

|

Take the four main bolts that were

holding the balancer on and cut 2" off the end of each bolt. Without the

balancer, they will bottom out. |

|

|

|

Re-install the four bolts. The torque

sequence should be criss-cross. Torque the bolts 34-37 lb ft, then an

additional 90-95 degrees. Then loosen them, and re-torque them to the same

sequence. Re-install the oil sump. You will not be able to bolt the lower

bolt in on the oil sump due to the balancer being removed, however, you can

still bolt the top bolt in. |

|

|

|

Scrape the gasket surface on both the

engine and the oil pan clean. Apply grey permatex to the oil pan. Allow it

to dry for about 30 minutes or until it is tacky. Re-install the oil pan.

Install a new oil filter. Put the lower fender liner back in. Put the tire

back on. Lower the car and torque the wheel down. It is best to let the

car sit overnight to allow the oil pan gasket to dry so that you do not have

oil leaks. Because you removed a large area of material in your engine

block, it now will take more oil. Add 6 quarts of oil and you are done!

Make sure to start your car and check for leaks before you go anywhere!

|

![]()

![]() Written by Torry Skurski

Written by Torry Skurski